Bringing MRC inventions to patients and other end-users relies on effective partnering with a commercial organisation; tailored licensing is at the heart of this. Last year our partnership with the MRC led to 19 licence agreements for translating the innovative research of scientists at the MRC Laboratory of Molecular Biology (LMB).

Meeting the global demand for cryo-EM

Grids are the ‘fuel’ for electron microscopes – a constant supply is needed to keep the microscopes running for structural biology research. More than one million grids are currently used around the world each year, and this is estimated to increase to two or three million per year by 2025.

The existing manufacturing methods require each grid to be handled individually by a sharp-sighted person with fine tweezers multiple times; a time-consuming process that is already failing to keep up with demand levels.

Chris’s group is focused on improving cryo-EM techniques. In 2020, they described a new type of improved all-gold grids called HexAuFoil® which completely eliminate the movement of the specimen during imaging, resulting in enhanced data collection and processing to gain more research insights.

Since then, many researchers have requested access to the new grids, but the team were unable to meet this demand due to the slow process of making grids one by one. Chris’ group took on the challenge of addressing this problem and increase access to the new HexAuFoil® gold grids.

Reimagining the grid manufacturing process

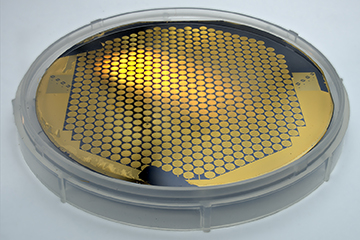

Starting with raw materials and borrowing methods from the semiconductor industry, researchers developed a new method in which grids are built from the bottom-up. This involves starting from a plain silicon wafer, patterning it with an array of small holes, then covering this with a thin metal foil before outlining each grid (3mm circle) and growing gold grid bars on top by electroplating, before finally releasing the individual grids from the wafer.

This method can make 600 grids at a time from a single 4-inch wafer, avoiding the need to handle the individual devices at any stage of the process. In a commercial setting, a small team will be able to make a minimum of 10,000 grids per day, which would help meet the growing global demand.

One challenge of the project was to ensure small enough holes were made on each grid. The grids require hole spaces of 300 nanometres – smaller than the wavelength of visible light – which was achieved using a technique called phase-interference lithography. In addition, the researchers needed to ensure the holes in the gold foil remained round in shape. They managed this by evaporating the gold film while cooling the template with liquid nitrogen in a method they named ‘cryoEvap’.

An essential contribution

LifeArc’s expertise was crucial in helping to bring a product to the market as quickly as possible.

As part of our partnership to provide technology transfer services to its researchers, LifeArc filed applications for a patent and trademark for the grids. We also marketed the technology and led licensing negotiations with interested companies in the field of cryo-EM. Throughout the process, we worked closely with the LMB researchers to tailor the intellectual property and commercialisation strategy to the specific development and market needs for this technology.

After evaluating the capabilities of each company, LifeArc identified Quantifoil as the company most able commit the resources and expertise required to manufacture the grids at scale. The first HexAuFoil products are expected to reach the market by mid-2022 and will make an essential contribution to the continuously growing cryo-EM field.

The work was funded by UKRI MRC, the Wellcome Trust, a Vice-Chancellor’s Award (Cambridge Commonwealth, European and International Trust) and a Sir John Bradfield Scholarship from Trinity College, Cambridge.

Find out more

Integrated wafer-scale manufacturing of electron cryo-microscopy specimen supports. Naydenova, K., Russo, CJ., Ultramicroscopy

Nature – Revolutionary cryo-EM is taking over structural biology